The combination of ferroelectrics and phase-change materials provides a route towards phase-change data storage at room temperature, without heating.

The current pace of data creation is truly staggering; in 2018 alone, it amounted to 33 zettabytes1. The relentless growth of data generation is likely to continue at even higher rates as more consumer electronics go online. Moreover, enormous datasets are required to increase the predictive accuracy of artificial intelligence algorithms. To keep up with this growth in data generation, the development of new materials, devices and systems is urgently needed. Now, the main question that needs to be answered is how to store and process the data in an efficient and sustainable manner.

Data has traditionally been stored as changes to the direction of magnetic domains in a hard-disk ferromagnetic film. However, these technologies are being replaced by solid-state disks, which are faster and have no moving parts. Data is usually stored using floating-gate transistors, relying on charges tunnelling through a high-κ dielectric onto a conductor. However, it is challenging to continue decreasing the size of these memory cells. It is, therefore, important and timely to consider alternative materials that can increase both memory density and performance.

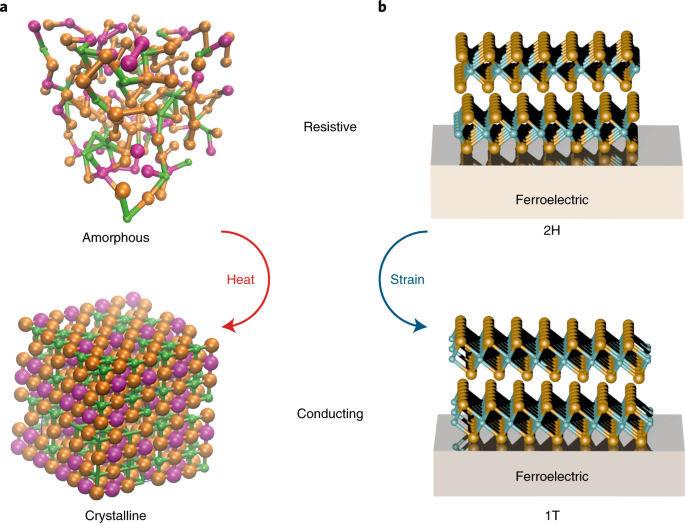

Phase-change materials (PCMs) offer a possible solution to the memory-scaling problem. Rather than storing charge, which can leak out of the memory cell, the data is encoded into the crystal structure of a material. Phase-change memories have enjoyed enormous commercial success as the active layers in rewriteable optical data storage media, such as DVD-RW2, and, more recently, in electrical phase-change random access memory3. Phase-change data storage typically relies on a reversible phase transition between amorphous and crystalline states. The low-resistance, crystalline state is formed by heating the material above its crystallization temperature, while the high-resistance state is formed by melting and quenching the material into its amorphous state. However, this process is energy-hungry, since the efficiency of thermally driven phase transitions is limited by entropy. Therefore, if a reversible phase transition could be induced without using heat, the realization of highly efficient data storage would become possible.

Phase transitions usually work to lower the free energy of the system. The different structural states of PCMs are stable at room temperature, because they are separated by an activation energy. In traditional PCMs, such as the GeTe-Sb2Te3 pseudo-binary alloys, heat is used to overcome this activation barrier (Fig. 1a). The significance of other factors, such as mechanical stress and electrostatic fields, is somewhat controversial. Indeed, the use of stress and electric fields to induce phase transitions in polycrystalline GeTe-Sb2Te3 materials is difficult because the crystal domains are randomly oriented and each domain experiences a different random strain or electric field. However, if PCMs are grown as a van der Waals superlattice, then physical fields, such as stress, can be used to alter the transition energy4.

In order to use physical fields to induce phase transitions, Hou et al., writing in Nature Nanotechnology, developed a new type of phase-change transistor that combines a van der Waals layered chalcogenide material, MoTe2, with a ferroelectric (Fig. 1b)5. When an electric field is applied to the ferroelectric, the MoTe2 layer is strained. The MoTe2switches between its semi-metallic and semiconducting phase at a threshold strain level of 0.33%, which provides a sufficiently large change in electrical conductivity to encode data. This result demonstrates how electric fields and strain can interact together to enable a structural phase transition between two crystalline states. Unlike phase transitions in GeTe-Sb2Te3 alloys, the MoTe2 film is not heated to melt-quench the amorphous phase — this promises radically lower energy consumption6, prevents chemical reactions with the electrodes7 and limits atomic diffusion8, all of which tend to occur at elevated temperatures.

Nanoscale materials can handle enormous strains9. Hou et al. exploited relatively thick MoTe2 films, which were composed of at least 18 stacked MoTe2 monolayers. Considering the extent to which 2D materials can be strained and the added strain energy, further decreases in switching energy can be expected for thinner layers of MoTe2. Moreover, dimensionally confined phase transitions lead to lower entropic losses10, which would further promote the switching energy reduction.

The potential applications for low-energy switching PCMs go beyond data storage. Recently the research community has shifted focus to tunable photonics applications, which include tunable filters, all-photonic processing networks and displays11. Clearly, the energy efficiency of phase-change ferroelectric transition metal dichalcogenides presents a new opportunity to design efficient active photonics devices.

Producing an ideal PCM is a daunting task. The material must switch reliably and repeatedly with low-energy pulses at a high speed. And, once switched, it must be stable across a wide range of operating temperatures. The concept of actively strained PCMs demonstrated by Hou et al. is an important step towards the realization of high-performance PCMs.

(원문: 여기를 클릭하세요~)